METAL FIRE AND SMOKE DOORS

FEATURES AND DESIGN:

A FIRE DOOR WITH NO COMPARISON

Quality beyond any doubt:

- Particularly robust door for safe operation over time.

- On request, fully insulated frame for “dry fitting” of the door.

- Tailor-made for any type of requirement.

- Fully galvanized door, including “hidden” parts.

- Built in hot-dip galvanized sheet metal, “Sendzimir” system.

- Corrosion protection even on the cut edges of the door.

- Painted with thermosetting epoxy-polyester powder baked at 180°.

- Remarkable thickness of the paint layer (more than 70 microns).

- Excellent resistance to corrosion.

- Inalterability to strong climatic variations, demonstrated by tests of 2000 hours with cycles from +60° to -10° and 75% and humidity.

- High aesthetic quality finish.

- Scratch-resistant embossed paint structure.

- Customization with a wide variety of colors.

Practicality of use:

- Remarkably robust structure that facilitates anchoring to the wall.

- Adaptable to any type of masonry.

- Possibility of choosing between different fixing systems.

- Significantly reduced installation times.

- Approvals for multiple applications in different types of walls.

- Wide dimensional range.

- Wide range of accessories.

Compliance with standards:

- Research conducted at Ninz using test equipment.

- Fire tests are performed according to EN 1634-1.

- Mechanical tests are performed for CE marking of accessories.

- Door fittings studied and dimensioned to meet the requirements of European standards.

- Careful choice of materials and construction methodology.

- Strict controls on the product in accordance with the characteristics.

- Absolute certainty of functionality over time.

- Provided with the documentation required by legal provisions.

Construction technology:

- Production uses modern and functional systems that utilize the most advanced technologies in construction methods, allowing for consistency of quality and high standards.

- The entire production process takes place within Ninz factories, from raw material to painted and packaged product, this ensures 360° control of the door.

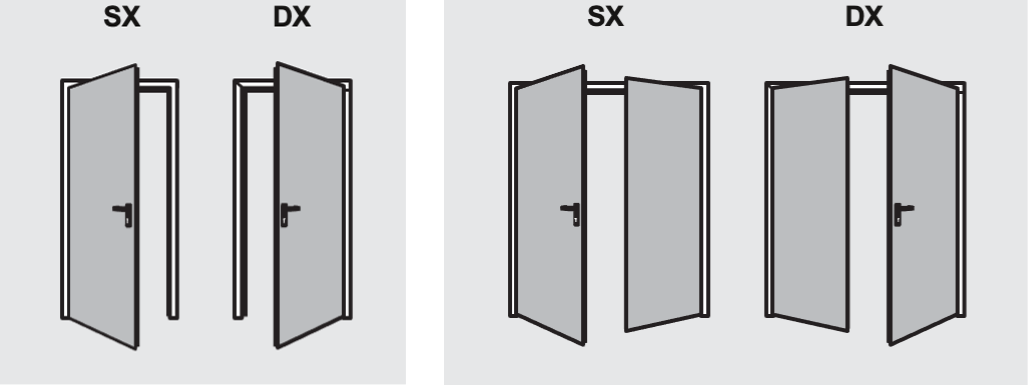

Opening direction:

The opening direction must be indicated when ordering.

Single leaf door available in the classes:

🔥 El 60

Double door available in the classes:

🔥 El 60

ELEMENTS OF THE DOOR

Leaf:

- Manufactured in hot-dip galvanized steel sheet “Sendzimir” system, pressure folded and spot welded.

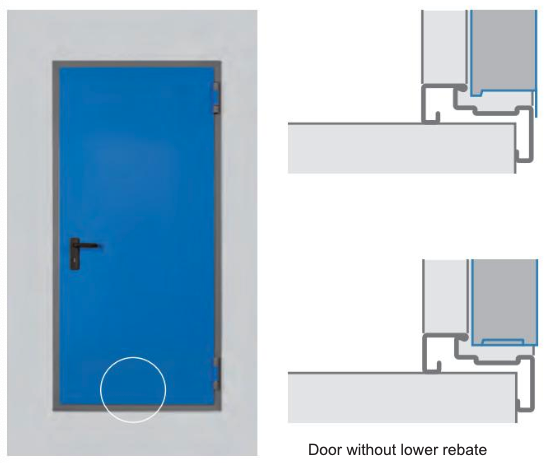

- Perimeter rebate on 3 sides, flat underneath.

- Internal reinforcements in galvanized steel profile “Sendzimir” system.

- Mineral fiber insulation panel treated and rigidly bonded to the sheet.

- Internal reinforcements for mounting door closers and accessories.

- Leaf thickness of 60 mm.

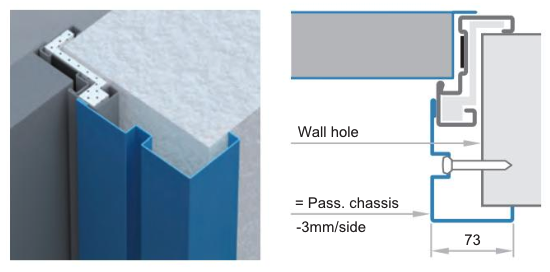

Standard frame:

- Robust profile with strong section.

- Made of hot-dip galvanized steel sheet “Sendzimir” system.

- Equipped with special brackets for corner mounting.

- Accommodations for thermo-expandable gasket and smoke gasket.

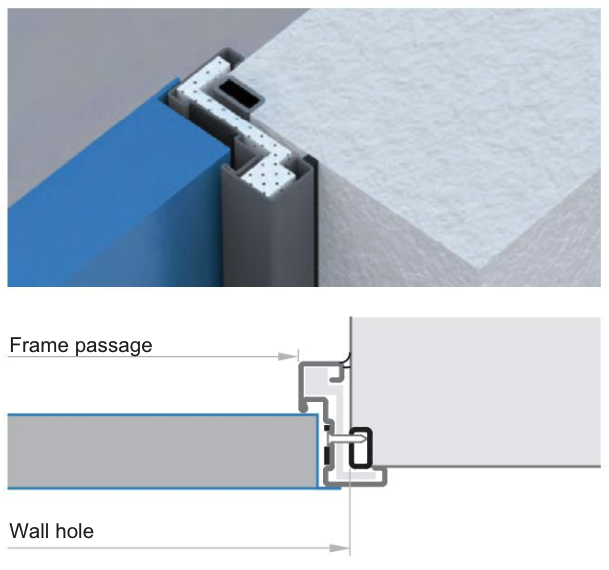

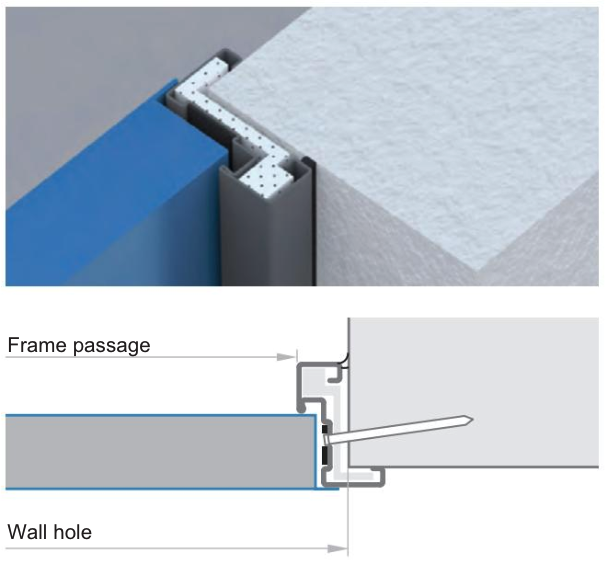

- Standard fixing by means of clamps.

- On request, fixing with dowels or screws.

- Lower spacer as mounting template.

- Mounting on finished floor.

- Black plastic strikers for latch and bolts.

- Frame for mounting in corner, tunnel and/or plasterboard partition.

Heat-expandable gaskets:

- Inserted in the perimeter profile of the frame and in the central profile of the doors.

Hinges:

- Two three-wing hinges, for each door.

- One bracket equipped with thrust balls and screws for vertical door adjustment, marked according to EN 1935, rated for load capacity up to 160 kg, durability 200,000 cycles, suitable for use on fire doors.

Bolt safety bolt:

- One or two security bolts in the leaf edge hinge side.

Door lock:

- Reversible lock with latch bolt and central deadbolt.

- CE marked according to EN 12209.

- Predisposed for Euro profile type cylinder.

Door handles:

- Fire door handle, in black plastic and steel core.

- Steel bottom plate with cylinder hole.

- Black plastic cover.

- Through fixing screws.

Selector selector:

- Double-leaf doors are equipped as standard with the RC/STD closing regulator for the correct closing sequence of the leaves.

- Marking Complies with EN 1158.

Counter-locking:

- Flush-bolt type for self-locking of the inactive leaf.

- Lever control for unlocking.

Top locking system on passive leaf:

- Device activated by the counter-lock located on the corresponding counter-lock.

Passive leaf lower latching system:

- Vertical steel-tipped rod that engages the corresponding lower lock.

- Bottom counter lock (floor lock) in black self-extinguishing plastic with stop.

Marking plate:

- Metal plate with door identification data, as required by law.

Finish:

- Standard painting with thermosetting epoxy-polyester powders in oven at 180°, surface with scratch-resistant embossed structure.

- Color to be chosen according to RAL chart.

Standard packaging:

- Single door protection by means of polyethylene (PE) stretch film.

- Individual packaging for each frame with polyethylene (PE) stretch film.

- Palletized in wooden crates.

NOTE

If repainting the door, follow the manufacturer’s specific instructions.

APPLICATION ON OTHER WALL TYPES

Different types of applications are possible, all rigorously certified and approved.

- Frame suitable for dry fixing by means of claws.

- Frame for application on plasterboard walls.

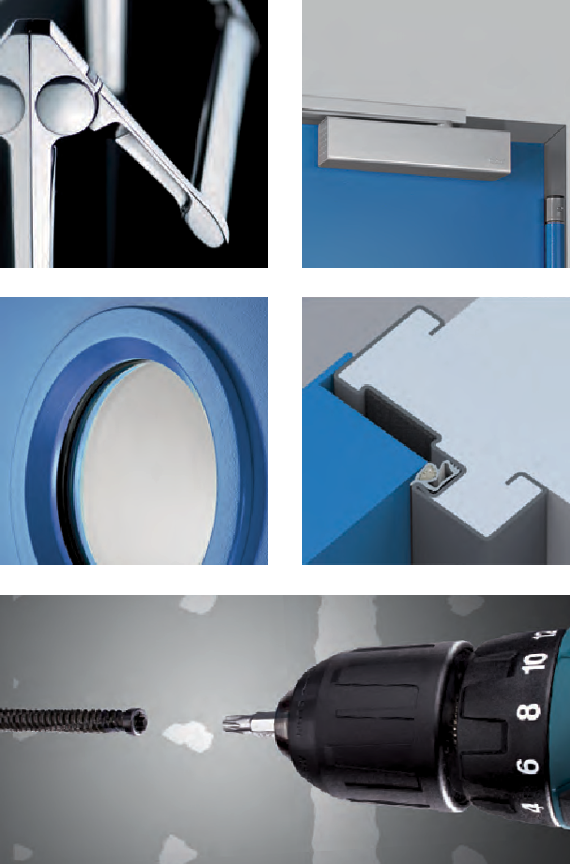

OPTIONAL ELEMENTS

On request it is possible to choose from a wide range of accessories according to the needs of the project.

Safety requirements:

- Panic exit doors (handles or safety handles).

- Emergency exit doors (see emergency handles).

- Normally open doors that must close in case of fire (see door retention systems).

Installation requirements:

- Flashings.

- Special fixing screws.

- Portholes and rectangular peepholes.

Access control requirements:

- By means of electrically activated locks.

- By means of handles.

- By means of locking magnet.

Improved performance:

- Stop seals.

- Cylinders.

- Door closers.

- Special closing regulators.

- Special handles.

Customization of finishes:

- Painting in colors to choose from the wide RAL range.

- NDD – Ninz Digital Decor, graphic representations made with special ink jets and half enamel protection Infinite possibilities of customizable decoration according to the configuration of the door.

- Steel handles.

- Colored handles.

SPECIFIC OPTIONS:

DOOR WITH FIRE RESISTANT GLASS

On request, EI 60 single and double-leaf doors can be equipped with round or rectangular portholes with fire-resistant laminated glass and corresponding screw-fastened retaining frames. Frame covers are standard on round portholes and on request on rectangular portholes.

Limits established by standards:

According to EN 1634-1 standards, the glazing of the tested specimen, when applied to the door, can be reduced in size but never increased, and vice versa, the edges around the glass can be increased and never reduced.

Therefore, the following limits meet these requirements.

Edges, bulls-eye position:

The “edge measurement” means the distance from the perimeter of the glass to the hole in the door wall.

NOTE

For rectangular portholes, frame covers are optional.

NOTE

The glass positions and dimensions indicated above are the standard ones.

Different positions and dimensions will only be taken into

consideration if they respect the minimum edges “a” and “b” and the maximum dimensions of the glass allowed by the certification

. The glass cannot be supplied disassembled unless it can be replaced. In the presence of portholes, it is always advisable that the door is equipped with a controlled closing door closer.

ATTENTION

For particular indications and recommendations on fire resistant glasses, please refer to the “Warnings” on the last page of this catalog.

DOOR HUGGER

IM 4

Fillers to be screwed to the Proget frame with the function of covering the hole in the wall. Made of hot-dip galvanized steel sheet “Sendzimir” system, painted with epoxy-polyester powders in the same color as the structure. Profile on three sides, 90° joint of the upper corners.

Complete with fixing screws. The holes in the frame for fixing the door panels are already drilled.

We recommend the combination with CR butt joint to hide the screw heads.

FRAME ON FOUR SIDES

On request, Proget single-leaf doors can be supplied with frame on four sides and the leaf with or without bottom stop. This solution is mainly used for technical compartments or recesses.

The four-sided frame is not intended for the following applications: doors installed in escape routes, double doors, doors with environmental features, application on plasterboard walls, combination with soffit.

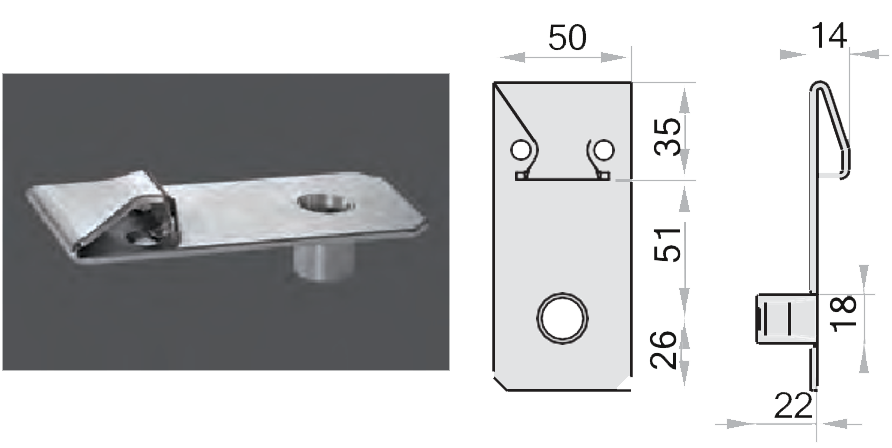

TOP STEEL STOPPER

Metal ground socket for Proget double door. Made of stamped steel and then galvanized. Includes the stop for the inactive leaf – the recessed bushing to insert the rod

It is used instead of the plastic bushing, where normally the doors remain open and there is passage of vehicles or trolleys.

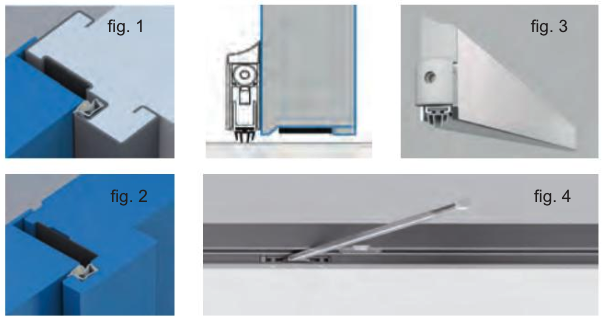

DEVICE “N626” – BUSHING WITH STOPPER OF HIDDEN DOOR

The N626 device is used as an alternative to fixed floor bushings, for two-leaf Proget doors that are normally held open. This device has the advantage of having the leaf stop (passive) embedded in the floor, which only comes out in case of secondary closing of the leaf. Designed to reduce the risk of tripping, it presents an additional practical and aesthetic advantage, while guaranteeing a correct closing of the door.

NOTE

The installation of this device must be carried out by specialized personnel.

SEALING GASKETS

Black extruded profile gasket to be cut and placed in the corresponding channel of the perimeter frame and in the central gasket of the 2-leaf doors.

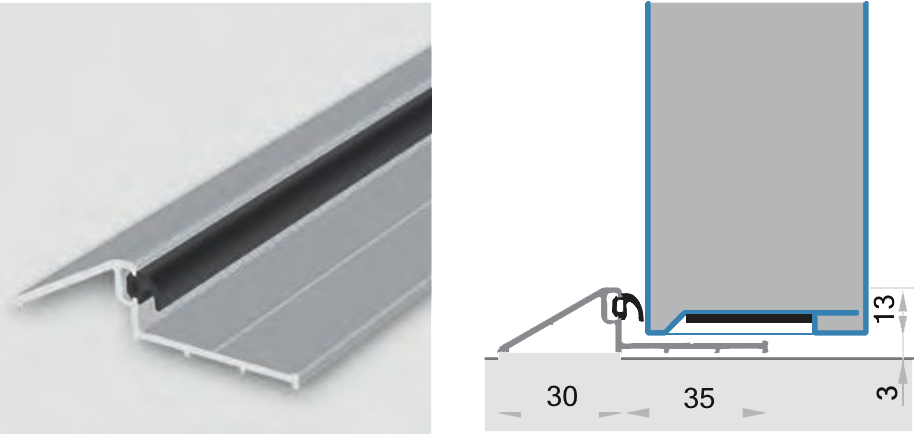

THRESHOLD

Anodized aluminum fixed threshold equipped with sealing gasket. For single or double leaf doors, it can be applied to the floor by means of screws and plugs (not included).

ADDITIONAL BENEFITS:

In the case of portholes of larger dimensions than those tested (300x400mm), up to a maximum of 400x600mm, a different thermal transmittance value must be requested, the acoustic performance remains unchanged.

For acoustic performance, in the case of double doors with L1 and L2 different from each other, take the Rw value lesser of the two;

- example 1: solid doors H=2150, L1=1000, L2=500, take 32 dB;

- example 2: solid doors H=2150, L1=1200, L2=1000, take 35 dB.

Optional fastening methods:

FIXING TO TABIQUE WITH SCREWS TO THE STRUCTURE

Certified system for single and double leaf EI 60 doors, to be fixed to the wall by means of screws on a metal sub-frame.

The sub-frame must be ordered separately from the door and taking into account that the internal dimension corresponds to the FM L x FM H dimension of the door.

For the technical characteristics of the subframe, please refer to the dedicated page in the “door accessories” section.

The frame is supplied already insulated with special insulating materials, complete with corner gaskets and bottom spacer to be screwed on site (except for single leaf doors with frame on all four sides).

The subframe fixing system allows a “completely dry” installation of the door, with the additional advantage of being able to install the door once the masonry work has been completed.

FIXING TO DRY PANEL WITH ANCHORS

Certified system for single and double leaf EI 60 doors, for wall fixing by means of anchors. Suitable for use in concrete, solid brick, semi-solid brick, lightweight concrete and others.

The frame is supplied already insulated with special insulating materials, complete with corner joints and bottom spacer to be screwed on site (except for single-leaf doors with frame on all four sides). This system allows a “completely dry” application of the door, without the need for any masonry work. The assembly of the door thus becomes a simple mechanical operation to be carried out together with the final adjustments

NOTE

When ordering, please specify exactly whether the door is to be fixed to the frame or directly to the wall with dowels.

MOUNTING SCREWS

For direct attachment to the wall or substructure we recommend the use of wall screws without the use of wall plugs. Please refer to the “door accessories” pages.